Machine Video

Home

Products & Solutions

Die Casting and Metal Forming

Thixomolding

Products

Thixomolding machine

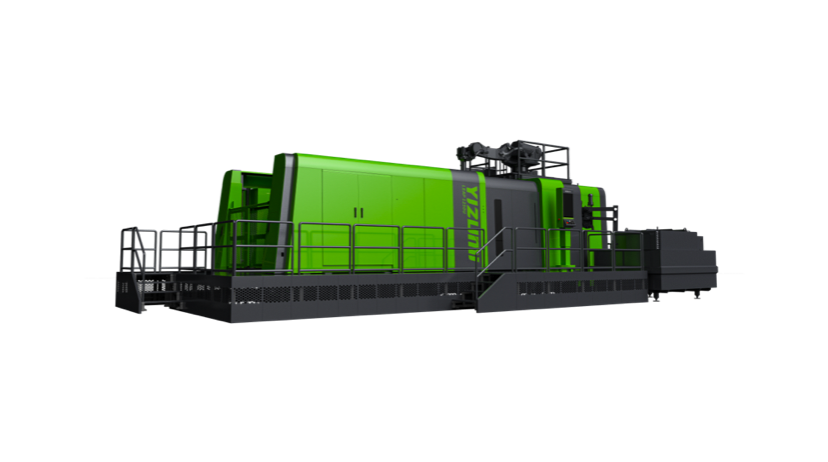

MG Series Thixomolding Machine

With 20+ years of experience, Yizumi created China’s first Thixomolding machine in 2009, earning industry recognition and a patent. In 2018, we launched a large injection model with a 2.5kg capacity through collaboration with German teams, matching the maximum injection volume of any competitor globally.

High Durability

Fast Response

Wide Range of Applications

Machine Video

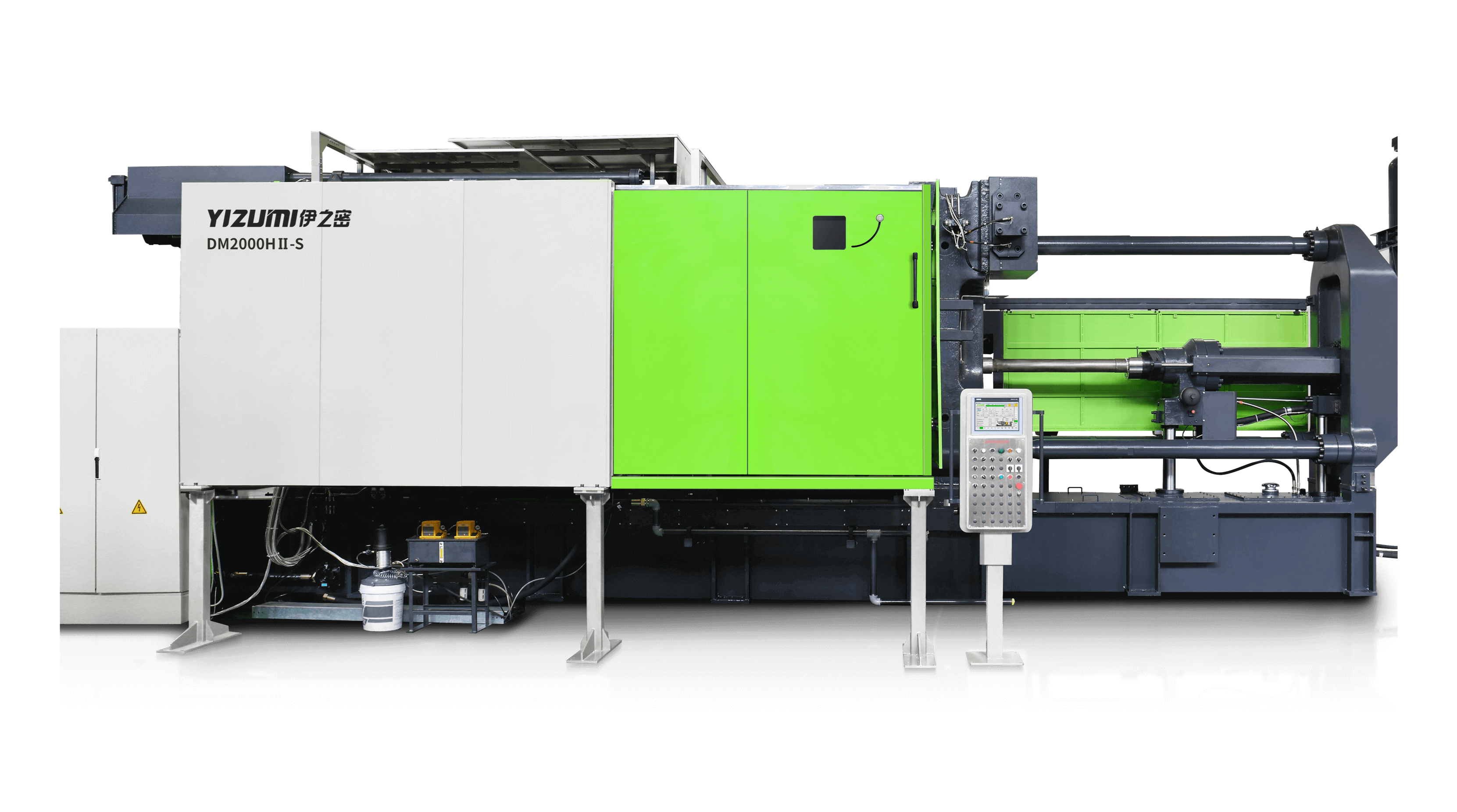

Industry-leading Injection System

High durability, fast response, large injection volume

A barrel made of European special steel; large diameter high-speed servo valve and bladder accumulators. The acceleration of the injection piston can reach 200m/s_x005f , and the flow rate a maximum of 4200 L/min.

Hot Runner Technology

- Reduce most of the gating, save 15% to 30% of mold materials;

- Reduce processing procedures and recycling costs;

- Easy to achieve standardization with good interchangeability.

- Reduce processing procedures and recycling costs;

- Easy to achieve standardization with good interchangeability.

Human-centered Design Control System

Fast response, accurate control and powerful function Thixomolding machine equipped with a state of the art Industrial computer has powerful functions and fast responses, realizing synchronous and accurate control for multiple functional areas. Humanized design interface and buttons make the operation more comfortable and convenient.

YiCMS Condition Monitor System (option)

Based on the Industry 4.0 concept "Internet and Integration", Yizumi’ s machine is equipped with interfaces for various peripheral devices and software programs to achieve a unified and standardized automation platform, providing customers with seamless integrated solutions.

Product Video

Industry Application

Relevant Recommendation

Relevant Products

Relevant Technologies

Service Process

01

Process/Mold Analyse and Design

- Raw materials selection

- Product design

- Mold flow analysis

- Mold design suggestion

02

Equipment Selection Suggestions

- Product performance

- Product quality

- Ease of use

- Safety requirements

03

Whole Plant Planning Advice

- Planning of production line

- Arrangements for people, machines, and materials according to process flow

- Peripheral automation

- Smart connection

04

Delivery Solutions

- Professional installation and debugging

- On-site operation training

- Molding process training

05

After Sales Solutions

- YFO services

- Preventive maintenance

- Device upgrade

Download

Contact Us

Please leave your message, and we will contact you soon!

I hereby give my consent for my personal data, collected and processed by YIZUMI in relation to my inquiry.

Contact Us

Please leave your message, and we will contact you soon!

I hereby give my consent for my personal data, collected and processed by YIZUMI in relation to my inquiry.